| | ghezzi tech: the quest for lighter wheels |  |

|

+24Street Birch GUZ21 1151 Grisonut spanner plantboy little750 sgw01 Steak wardest grisorosso Ahdammit beetle mark111 tocino Guzziboy66 Pete Roper Scot p Uzidzit Canyon Carver Oz1200Guzzi DungeonMaster pauldaytona 28 posters |

|

| Author | Message |

|---|

Guzziboy66

Grignapoco

Posts : 146

Join date : 2013-07-26

Age : 57

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Fri Aug 15, 2014 7:41 am Fri Aug 15, 2014 7:41 am | |

| Ghezzi,

I understand what you're doing and have been ravenously following along. But Uzi's explanation of hardening and tempering and ramming is hard for me to wrap my head around... I should have quoted his post in mine. I love what you're doing and can't wait to see the finished product.

Eric | |

|

| |

Canyon Carver

Sfregiato

Posts : 467

Join date : 2014-06-13

Age : 74

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Fri Aug 15, 2014 8:49 am Fri Aug 15, 2014 8:49 am | |

| Obviously the wheels are worth more than a GRiSO at this point. Amazing concept and execution of course!  | |

|

| |

pauldaytona

Fra Cristoforo

Posts : 477

Join date : 2014-01-07

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Fri Aug 15, 2014 11:15 am Fri Aug 15, 2014 11:15 am | |

| But why the spline mounting? Is center hole to small to mount with original bolts/mounting flange?

| |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Fri Aug 15, 2014 3:39 pm Fri Aug 15, 2014 3:39 pm | |

| Eric, I too have to admit that hardening and ramming are terms I previously used in relation to other non-motorcycling activities. Already stated, "I've given up beer and sex" Uzi is fortunate to have these skills/knowledge/access to machinery, for him it is only time allocation. I believe he also has (access to) CNC machines. I'm Jealous. CanCar, you need to view this project thru AUD$ goggles. The fact I suffer from OCMD, Obsessive Compulsive Modification Disorder is not helping.  I'm currently bidding on a used CARC and swingarm, wondering if I can make smaller lighter carbon housings? Paul, from mammary (I could go tits up here), memory carbon centre hole 84mm dia. Guzzi 4 stud is 86mm PCD. Bolt flanges are 24mm dia. BST 5 stud is 112mm PCD. We could have relieved the carbon to fit standard wheel bolts. Then shift the 5 BST M6 screw holes further outwards, all loads would pass through those 5 x M6 screws. By not messing with the structural integrity of the carbon, and duplicating BST hub design/fitment and attachment, I should, I say should remain within the realms of safety. Whilst we are all dying, I really don't want to die prematurely. Also, I haven't reached the point of "no return", I can still fit the original BST hubs and use this wheel on my RS485. Drive (chain) loads for original BST passed thru left side of hub, 5 x M8 screws. By using a splined drive shaft keyed to both alloy hubs, all power and brake loads will be shared uniformly. There is one point of concern, and I admit I usually over engineer things. Having 4 wheel studs, if one breaks you won't crash and burn, having a single centre wheel nut means you can only ever have a single failure. Never gave it a single thought when I owned a Ducati. SINGOLA MOZZO DADO (SMD) |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Mon Aug 18, 2014 5:21 pm Mon Aug 18, 2014 5:21 pm | |

| SINGOLA MOZZO DADO (SMD)

The single axle nut has presented a problem. Measure once cut twice.

After taking all the tech specs for the Ti axle nut directly from the Pro Bolt website, we machined the axle to suit M33 x 1.25. Pity that the nut thread actually measures 1.5mm pitch.

Still trying to find out if Pro Bolt actually offer a 1.25 pitch nut, or their webmaster stuffed up. Their part # is TINUT33125002, 33125 meaning M33 x 1.25

Just had a call from Pro-Bolt, apparently the one part # can be had with different pitch threads, designated by Z1, Z2 or Z3. But these digits and sizes aren't on their public website. Doh!

Why aren't they listed as 33125, 33150 and 33200? That'll be another $81.05 thank you very much.

And now the Tool Maker just called, wire cutting the hub internal splines will only be $350. Gee, looks like I won't be paying tax next year either. |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 24, 2014 1:10 am Sun Aug 24, 2014 1:10 am | |

| I had some concerns regarding my engineering design, check out this ZX14 with billet single sided swingarm and 240 wide rear tyre. Take notice at the 2:07 mark of the axle size, hubs and splines. This handles 200+HP, wheelies and drag racing etc. [You must be registered and logged in to see this link.]Still shot from 2:07 [You must be registered and logged in to see this image.]My axle shaft is 40mm dia. has more (36) splines, has to support less weight and less than half the power. I will be using M33 x 1.25 Titanium axle nut actually designed for the rear sprocket cover on a 748-998 Ducati. Typically SS swingarm bikes use closer to 48mm axle nuts, but the ZX14 has something quite small. I have contacted Roaring Toyz for their axle dimensions for comparison.

Last edited by ghezzi on Fri Aug 29, 2014 6:47 pm; edited 2 times in total |

|

| |

pauldaytona

Fra Cristoforo

Posts : 477

Join date : 2014-01-07

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 24, 2014 3:56 am Sun Aug 24, 2014 3:56 am | |

| - ghezzi wrote:

- I had some concerns regarding my engineering design, check out this ZX14 with billet single sided swingarm and 240 wide rear tyre. Take notice at the 2:07 mark of the axle size, hubs and splines. This handles 200+HP, wheelies and drag racing etc.

[You must be registered and logged in to see this link.]

My axle shaft is 40mm dia. has more (36) splines, has to support less weight and less than half the power. I will be using M33 x 1.25 Titanium axle nut actually designed for the rear sprocket cover on a 748-998 Ducati. Typically SS swingarm bikes use closer to 48mm axle nuts, but the ZX14 has something quite small. I have contacted Roaring Toyz for their axle dimensions for comparison. the bigger the axle is, the less flex you have. The axle on a chain bike goes through a bearing and is loaded on both sides of the bearing. In this case all alu parts are there as spacers, and force is in the axle. If you want something similar, your axle should start at the carc flange, and go through the centre. In that case I wonder why you took all glued parts of the wheel. But I have no drawings of what space there, because that gives what is possible. look here: [You must be registered and logged in to see this link.]And the millepercento alba has also something worth a look, their SCIGHERA has a spoked wheel but similar hub | |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 24, 2014 3:51 pm Sun Aug 24, 2014 3:51 pm | |

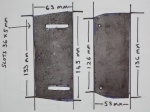

| Paul, go to BST web site and look at their hub design for chain drive bikes first! 1. 2.5+kg of mass alloy lumps to hold bearings and sprocket, notice to that the biggest chunk is on the left side, mounted via M8 bolts (& internal nuts) to take drive loads. 2. Right side hub is the disc carrier, mounted by M6 screws to absorb brake loads only. 3. Head of my axle (hardened 4340) is keyed into the hollow centre of the CARC flange (crownwheel gear). It is perfectly centred as per stock wheel mounting flange and cannot slip or spin. 4. But the axle is first pressed thru a steel (4340) plate which then bolts directly to the CARC flange as per stock wheel. This plate also doubles as the stock brake disc carrier, the disc obviously must line up with the caliper, and disc bolt heads also trigger the speed sensor. Normal drive system for (chain drive) single side mounted wheels, are 4 pins that locate into the alloy centre of the wheel. Why didn't I do this? Coz the primary drive loads would then pass directly thru the M6 screws on the right side of the carbon centre. Why didn't I turn the wheel around? Coz the slanted spokes would have then been leading, not trailing as per intended BST design. 5. Axle has splines 54mm long, both new alloy hubs (left and right side) are splined to match so drive (& brake) loads are shared equally. Five M8 bolts and nuts on the left, and five M6 screws on the right. Also, right hub has been counter bored for the 4 wheel studs that hold the axle plate to the CARC flange. There is only 30mm between CARC flange and carbon face. So you will not even see my right side hub if it is anodized black. Below is a photo of all the parts I removed from the BST rear wheel, weighing 2.55kg [You must be registered and logged in to see this image.]" /> In remanufacturing my hubs, we'll have none of the centre or left hubs (above) except an axle nut receiver, and my right side hub will be less than half the size of what you see here. Update/edit 1st Oct. And here are all the replacement parts for my BST to CARC fitting. [You must be registered and logged in to see this image.]" /> By comparison, a Ducati style (offset) wheel would need a 60+mm spacer and the axle would also be 30mm, or 34% longer. In my uneducated novice engineering opinion, the Euro700 hub offered by Ipothesys creators is a bad design based on the convenience of available alloy wheels. Wheel bearings for a Ducati single sided swinger are located in the large swingarm hub, which is central to the wheel/tyre line. CARC wheel bearings are mounted to the far right of the wheel/tyre centre line. The offset loading is why CARC bearings shit themselves, occasionally. A longer axle would be more prone to flex, as well as increasing the axial loading on the CARC bearings.

Last edited by ghezzi on Wed Oct 01, 2014 2:58 am; edited 6 times in total |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Tue Aug 26, 2014 9:42 pm Tue Aug 26, 2014 9:42 pm | |

| Here's todays $300 spend, just cutting the hub splines by wire cutter. [You must be registered and logged in to see this image.]40mm OD, 36 spline. The two small rings are my offerings to the "God of Speed"

Last edited by ghezzi on Fri Aug 29, 2014 7:45 pm; edited 3 times in total |

|

| |

tocino

Nibbio

Posts : 569

Join date : 2014-06-21

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Wed Aug 27, 2014 9:04 pm Wed Aug 27, 2014 9:04 pm | |

| | |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 12:40 am Sun Aug 31, 2014 12:40 am | |

| Well here's the finished front wheel, just need a new 17" front guard. [img] [You must be registered and logged in to see this image.][/img] Can't find a Bonneville SE front guard, do you guys think a GRiSO guard would fit and look right? |

|

| |

mark111

GRiSO Capo

Posts : 279

Join date : 2014-04-23

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 1:07 am Sun Aug 31, 2014 1:07 am | |

| A GRiSO guard woud look good but the mountings are cast on the lower fork leg so you couldn't mount it without significant modification.

There is probably a Jap bike with something easier to mount. | |

|

| |

beetle

GRiSO Capo

Posts : 10200

Join date : 2013-09-30

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 1:08 am Sun Aug 31, 2014 1:08 am | |

| Too hard to fit a GRiSO guard? G has USD forks with mounts fore and aft of the leg. --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- ..[You must be registered and logged in to see this image.].In GRiSO we trust! . | |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 1:18 am Sun Aug 31, 2014 1:18 am | |

| I was trying to determine if the GRiSO guard was 1 or 2 piece. As in black guard and silver mount bracket. Bella's guard mounts up under the fork brace but the 18" radius is now all wrong with the 17" tyre. |

|

| |

beetle

GRiSO Capo

Posts : 10200

Join date : 2013-09-30

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 1:38 am Sun Aug 31, 2014 1:38 am | |

| GRiSO is one piece. What about a Breva 750 guard? [You must be registered and logged in to see this image.]--- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- ..[You must be registered and logged in to see this image.].In GRiSO we trust! . | |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 1:47 am Sun Aug 31, 2014 1:47 am | |

| I thought the small block Breva had a front tyre skinnier than 120/70 x 17". Prefer classic style guard like Bonneville SE [img] [You must be registered and logged in to see this image.][/img] |

|

| |

beetle

GRiSO Capo

Posts : 10200

Join date : 2013-09-30

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 2:02 am Sun Aug 31, 2014 2:02 am | |

| CLICKY

CLICKY --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- ..[You must be registered and logged in to see this image.].In GRiSO we trust! . | |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 2:23 am Sun Aug 31, 2014 2:23 am | |

| Thanks Beetle, every time I googlied in the last 2 weeks all I got was fender extenders.

Bought the 2nd (standard length) guard for AUD$138 delivered. |

|

| |

beetle

GRiSO Capo

Posts : 10200

Join date : 2013-09-30

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 2:26 am Sun Aug 31, 2014 2:26 am | |

| --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- ..[You must be registered and logged in to see this image.].In GRiSO we trust! . | |

|

| |

Ahdammit

Tanabuso

Posts : 65

Join date : 2014-08-17

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Sun Aug 31, 2014 1:23 pm Sun Aug 31, 2014 1:23 pm | |

| Nice work John  | |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Tue Sep 02, 2014 8:53 pm Tue Sep 02, 2014 8:53 pm | |

| Hey, I'll be gluing my new hubs to the carbon wheel with Araldite, no shit! Ok, it's very expensive Araldite. Visited local supplier to the composite industry, got a guided tour through the warehouse and shown all sorts of materials for different purposes. Feel a lot more comfortable about my dream carbon CARC and swingarm ........................................ Anyway, the Araldite cost $150 for two small tins, but I'll have plenty left over if anybody else wants a set of plastic wheels.  Got repeatedly asked today (in a local Guzzi shop), "How do I justify spending $3k on a pair of wheels"? I had no answer. Thought about it later; Why do I have to justify anything? Didn't have the heart to tell him I've probably spent another $3k in developing hubs and axle etc. Turns out my assailant owns 3 pieces of old Jap shit that ain't worth a nob of goats poop between them, but what do I care. |

|

| |

pauldaytona

Fra Cristoforo

Posts : 477

Join date : 2014-01-07

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Wed Sep 03, 2014 1:14 am Wed Sep 03, 2014 1:14 am | |

| The justify thing is irrelevant. When you do only resonable justifyable things, you get nowehere. Then better buy a sv650 | |

|

| |

beetle

GRiSO Capo

Posts : 10200

Join date : 2013-09-30

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Wed Sep 03, 2014 1:46 am Wed Sep 03, 2014 1:46 am | |

| - ghezzi wrote:

- Why do I have to justify anything?

I do think you're slightly mad, but if it makes you happy you don't need to justify yourself to anybody. Having said that, we reserve the right to take the piss.  --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- ..[You must be registered and logged in to see this image.].In GRiSO we trust! . | |

|

| |

Pete Roper

GRiSO Capo

Posts : 10711

Join date : 2013-05-29

Age : 67

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Wed Sep 03, 2014 3:01 am Wed Sep 03, 2014 3:01 am | |

| Oh he's barmy! But in my book he's dedicatedly and healthily barmy!

Pete | |

|

| |

Guest

Guest

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  Wed Sep 03, 2014 3:41 am Wed Sep 03, 2014 3:41 am | |

| Come on, Takin' the Piss is our national sport, you boys can do better than that.

I was a finalist for our Olympic team in "dummy spitting", with a pb of 23.456m. Missed, '' by that much. |

|

| |

Sponsored content

|  Subject: Re: ghezzi tech: the quest for lighter wheels Subject: Re: ghezzi tech: the quest for lighter wheels  | |

| |

|

| |

| | ghezzi tech: the quest for lighter wheels |  |

|